Grimsthorpe Castle

Grimsthorpe Castle

A Wonderful Castle in the heart of Lincolnshire. Grimsthorpe Castle is a historic house that lies within a 3000 acre park of rolling pastures, lakes and woodland landscaped by Capability Brown.

Overview:

Grimsthorpe has been the home of the de Eresby family since 1516 when it was granted by Henry VIII to the 11th Baron Willoughby de Eresby on the occasion of his marriage to Maria de Salinas, lady-in-waiting to Queen Katherine of Aragon. It is now owned and managed by The Grimsthorpe & Dummond Castle trust.

The Requirement:

There are many lights within the rooms to create an intimate and home-like atmosphere and to display the contents to the many visitors the castle receives each year.

The numerous chandeliers and standard lamps consume a vast amount of energy annually. The problem the trust needed to overcome was how to save energy whilst maintaining the aesthetics of the standard incandescent lamps and visually displaying the exhibits of the room to maximum effect.

The Solution:

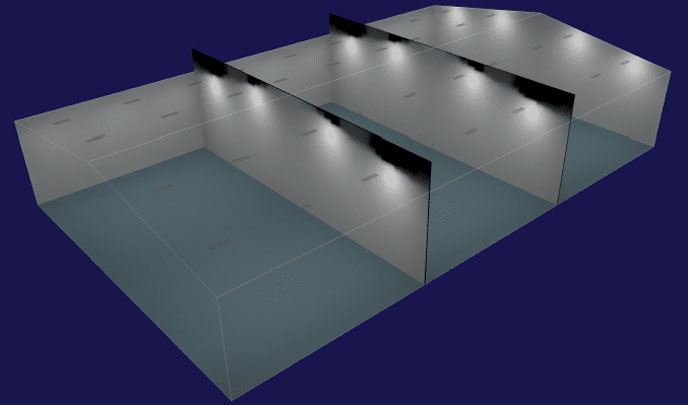

The Prolite Projects team conducted an energy survey at the castle to identify potential energy savings that could be achieved through an LED upgrade installation throughout the castle.

By upgrading the standard power hungry incandescent lamps to Prolite’s new range of aesthetically pleasing LED filament lamps the energy usage in the rooms where lamps have been changed has reduced by over 95%.

The return on investment for the Castle was achieved in less than 3 months! The 2 year product warranty offered by Prolite ensures that the savings will be made time and time again.