Workshop Lighting

Ensuring employees can see clearly whilst working on difficult projects and operating machinery is a must within all production and workshop areas. Workshop areas are often designed to provide higher light levels to maximise visibility and minimise mistakes during the production process. Good colour rendering is imperative for product production and our previous installations have resulted in a dramatic improvement to levels of staff productivity within workshop and production area environments.

The Prolite Projects team works closely with our clients on workshop lighting projects to create both an energy saving solution for the manufacturer and improve the working environment for the production team. Through building close working relationships with our clients, we can produce and develop products to exact specifications, to meet specific lighting level requirements.

The Prolite Projects team are experienced in on-site surveying. Once information on the current lighting system has been gathered, the team can recommend the correct and most suitable lighting solution to be installed. The recommended lighting fixtures will offer energy savings and lower maintenance costs for the site ongoing. Both energy saving calculations and return on investment will be included within our proposal to help our clients make the right decision for their business. Additional energy saving features such as occupancy sensing will further enhance the energy saving and therefore cost saving that an LED upgrade can generate clients.

The Prolite Projects team have planned and delivered installations that required non-standard products for workshop lighting applications. As a UK manufacturer, we have a great R&D team able to develop products to meet the specific requirements of the client’s specification. This is especially useful as the items required for certain installations are not always readily available and ‘off the shelf’ to purchase from the standard Prolite range. The process of creating lighting solutions for workshop areas requires a close working relationship with the client to ensure that the solution will meet the specifications of the client’s application guidelines.

Project Example 1

The client was looking to upgrade their traditional fluorescent office lighting to create a pleasant working environment for the area, staffed throughout a 14 hour day. The products required to be HMRC ECA compliant due to funding criteria requirements for the site. Prolite LED products were the obvious choice.

| WATTAGE | ||

| Before LED | After LED | Total Watts Saved |

| 26172W | 9680W | 16492W |

| COST P/A | ||

| Before LED | After LED | Saving |

| £11,460 | £4124 | £7336 |

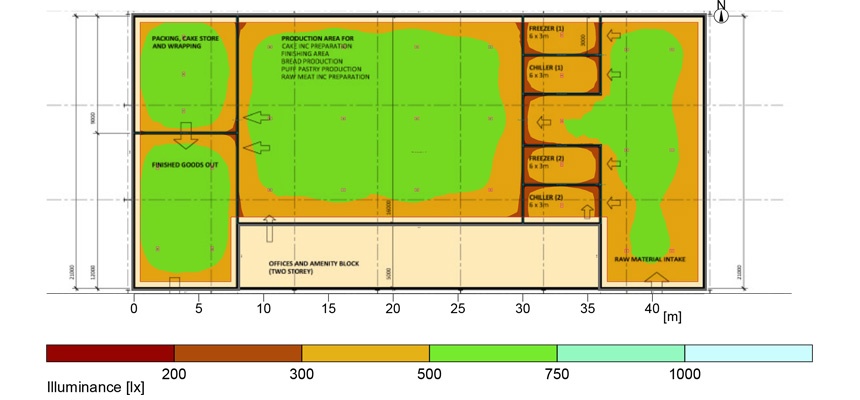

Project Example 2

A local bakery that was passionate about finding a low energy solution to their current lighting system on site. The current system used power hungry metal halide fittings that needed constant maintenance with bulb failures at a very high cost due to the 10m current mounting height of fittings. Prolite’s LED lighting products offered a 5 year maintenance free solution whilst maintaining the sites current 500 lux average specification.

| WATTAGE | ||

| Before LED | After LED | Total Watts Saved |

| 13800W | 4500W | 9300W |

| COST P/A | ||

| Before LED | After LED | Saving |

| £6044.40 | £1971.00 | £4073.40 |

Trial and Evaluation

Capital Cost Recovery

Finance

OTHER CASE STUDIES CARRIED OUT BY THE PROLITE PROJECTS TEAM

On-Site or Remote Lighting Survey Available

Prolite Lamps are able to offer customers either an on-site or remote LED Lighting survey for all types of different applications nationwide. The Prolite Projects team offer advice upon the following.