Cold Storage Lighting

Traditional industrial lighting has proven outdated compared to the performance of Prolite LED industrial lighting within cold storage faciliti

Lighting within cold storage facilities is one of the more challenging tasks in the lighting industry, as few traditional products perform well in cold environments.

When LED lights are used to replace less efficient light sources such as Metal Halide or Sodium Lighting, there is an additional saving gained when used in refrigerated environments. In addition to the lighting circuit’s reduced energy consumption, there will also be less power consumed by the cooling system to maintain the desired temperature. This is due to the higher efficiency of the LED light producing less waste heat that previously had to be removed by the refrigeration system.

Cold storage units are often involved with food storage and therefore the glass used in the lighting installs need to be safe. Prolite’s LED products are glass free and built specifically so they are food safe with safety features in place in case of damage. Prolite’s luminaires are both dustproof and waterproof and are designed to operate at the low temperatures that cold storage facilities operate at with maximum efficiency.

Our LED products offer the following benefits over old technology light sources:

No mercury of phosphor

HMRC ECA compliant

Many more . . .

Lighting schemes

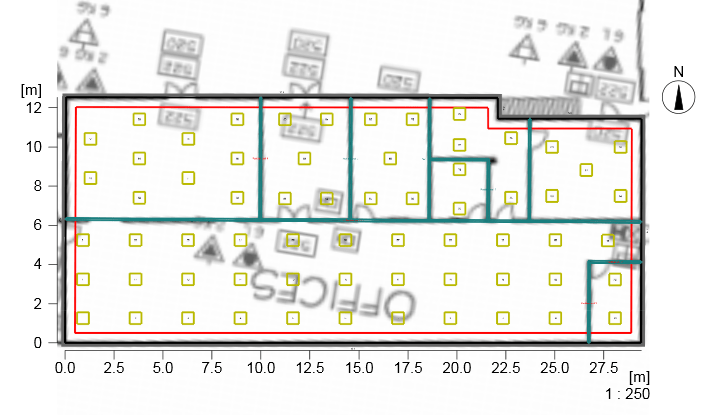

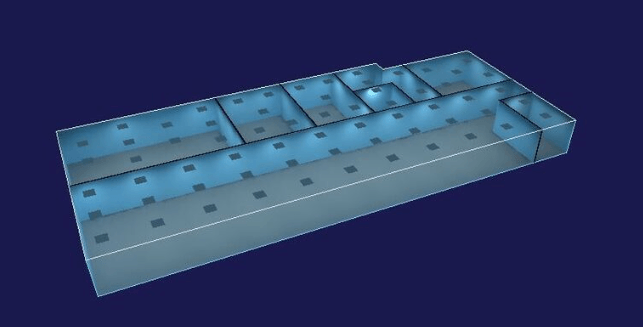

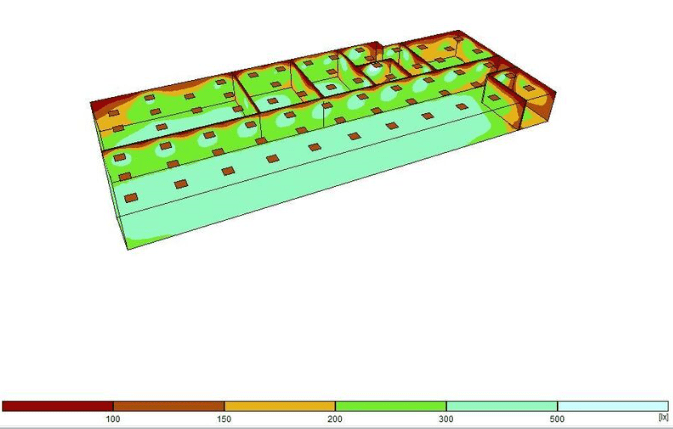

With Prolite designing a lighting scheme for your site, it removes any guesswork in light level critical areas prior to installation. Our lighting design service includes:

Photometric data

LUX level confirmations

Energy savings calculations

3D imagery

Project Example 1

The below project is a cold storage distribution centre for a food processing company in the UK, hence the requirement for non-glass LED light units to be installed. A light level of 400 lux was specified by the client to ensure picking and packing errors are minimised post refit.

| WATTAGE | ||

| Before LED | After LED | Total Watts Saved |

| 42320W | 18720W | 23600W |

| LUX* | ||

| Before LED | After LED | LUX Gained |

| 340 LUX | 402 LUX | 62 LUX |

*Lux is a standardised unit of measurement of light level intensity (which can also be called “illuminance” or “illumination”)

| COST P/A | ||

| Before LED | After LED | Saving |

| £44,486.78 | £19,678.47 | £24,808.32 |

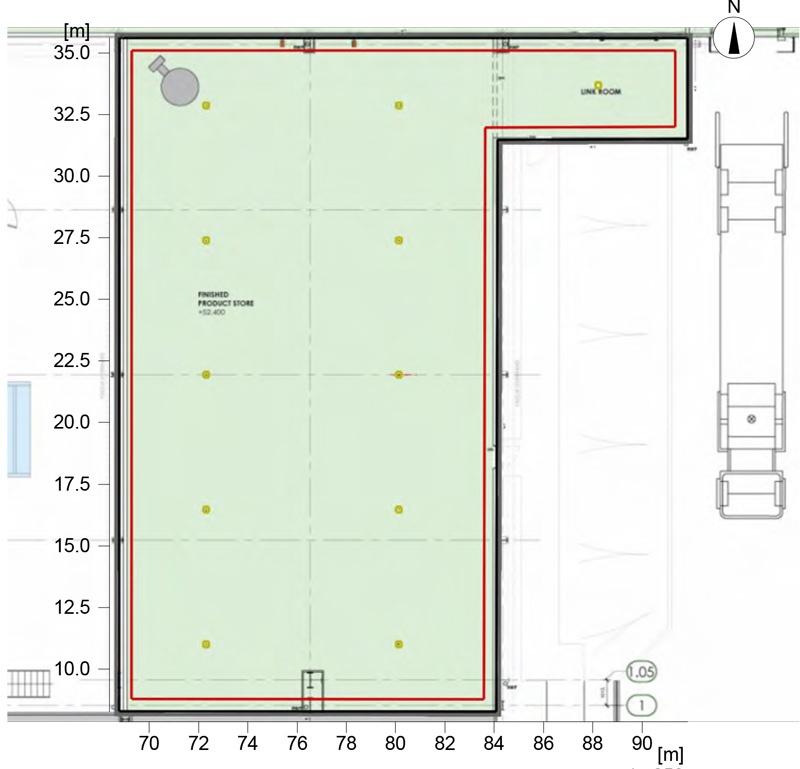

Project Example 2

This project is for another large food processing plant’s new production and packaging areas. This project was a new build where the client was passionate about reducing the companies carbon footprint, whilst maintaining a good level of light within the areas using the most efficient high powered LED light units possible. Prolite was the obvious choice.

| Wattage | LUX |

| 1650W | 450 LUX Average |

*Lux is a standardised unit of measurement of light level intensity (which can also be called “illuminance” or “illumination”)

Trial and Evaluation

Capital Cost Recovery

Finance

OTHER CASE STUDIES CARRIED OUT BY THE PROLITE PROJECTS TEAM

On-Site or Remote Lighting Survey Available

Prolite Lamps are able to offer customers either an on-site or remote LED Lighting survey for all types of different applications nationwide. The Prolite Projects team offer advice upon the following.